ProF2

Software per la progettazione e calcolo dei serramenti

ProF2, disponibile in quattro versioni, è il modulo principale della Suite firmata Fom Software Technology. Semplice da utilizzare, grazie anche all’ambiente di progettazione su CAD, ProF2 supporta l’azienda in ogni area, da quella commerciale a quella produttiva.

Vantaggi di ProF2

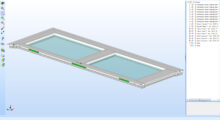

- Progettazione in ambiente CAD con disegni in scala

- Gestione di infissi di ogni forma: rettangolare, fuori quadro, ad arco

- Utilizzo di sistemi di alluminio, PVC, alluminio-legno, ferro e acciaio

- Archivi profili precaricati

- Archivi modificabili in autonomia dall’utente

- Calcolo analitico del costo dei serramenti e dei margini di contribuzione

- Sviluppo di preventivi esportabili in PDF, Word o Excel

- Calcolo di listini-prezzi a griglia

- Calcolo Uw e verifica dei limiti in funzione della zona climatica

- Stampa delle dichiarazioni di conformità per i bonus fiscali

- Gestione marcatura CE

- Gestione magazzino

- Ordini ai fornitori

- Stampa dei documenti per la produzione

- Ottimizzazione del taglio

- Rendering 3D parziale o completo della tipologia con le lavorazioni

- Invio dei dati alle macchine di produzione: troncatrici, centri di lavoro, saldatrici ecc.

- Disegni e sezioni esportabili in DXF e DWG